Our goal of field service for turbomachines: give our customers the full control over budget and downtime during their outage without the hard times of coordination.

At SPIE Turbomachinery, we aim to offer to customer a comprehensive and turnkey site service on the complete power unit including all auxiliaries and covering multi technical skills. Due to that approach, customer can focus on its own process, leaving the rotating equipment (turbines, alternators, compressors, turbogenerators, pumps,…) and its environment under the complete management of SPIE Turbomachinery.

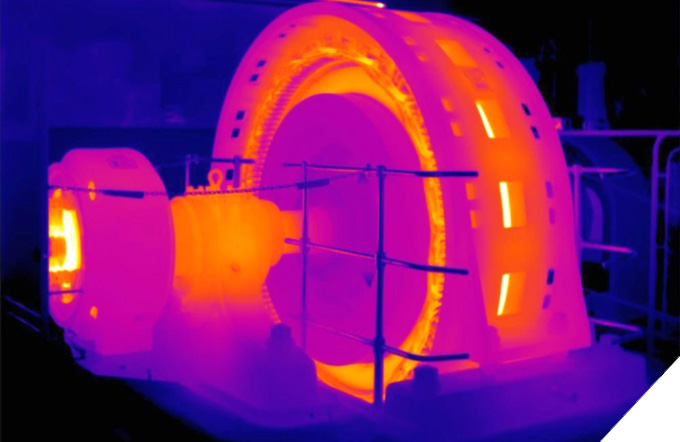

PREDICTIVE MAINTENANCE

- Vibration analysis

- Hot spot check by thermal camera

- NDT inspections

- Borescopic inspection

- Surveys

- steam mapping

- performance assessment

- condition survey

SCHEDULED MAINTENANCE

- Fully equipped workshop container for on-site machining

- Mobile machining machine for finning and body machining

- Mobile balancing machine

- Laser alignment

- Special tools (over 75 different types in stock)

- Mobile NDT inspection booth

CORRECTIVE MAINTENANCE

- On call intervention

- Turbine and auxiliaries correction or reconstruction

- On-site special repairs

- bearing housing machining

- bearing & seals alignment

- blade tip machining

- blade locking pin drilling

- …

COMMISSIONING & TROUBLESHOOTING

- Loop checks with control systems

- for gas turbines

- GE® Mark IV, Mark V & Mark VI

- PLCs (GE® Fanuc™, SIEMENS® S7, Schneider®,

- for steam turbines

- WOODWARD® 505 & VOITH® TurCon™

- electro-mechanical controls

- for gas turbines

- Live checks

- Steam mapping

- Compressor mapping

- Functional testing

- Troubleshooting rotating equipment and auxiliaries