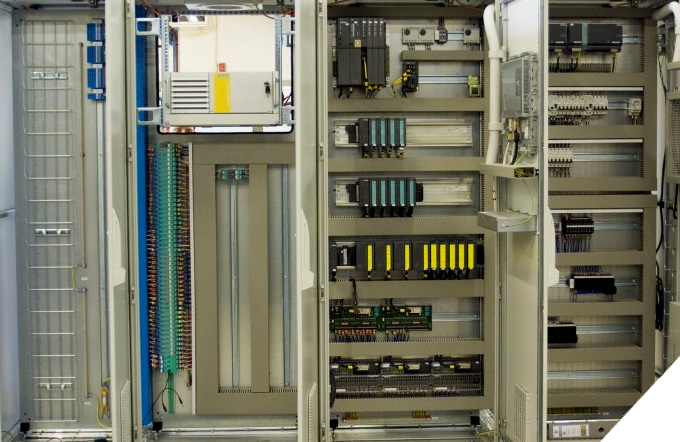

CONTROL SYSTEM RETROFITS

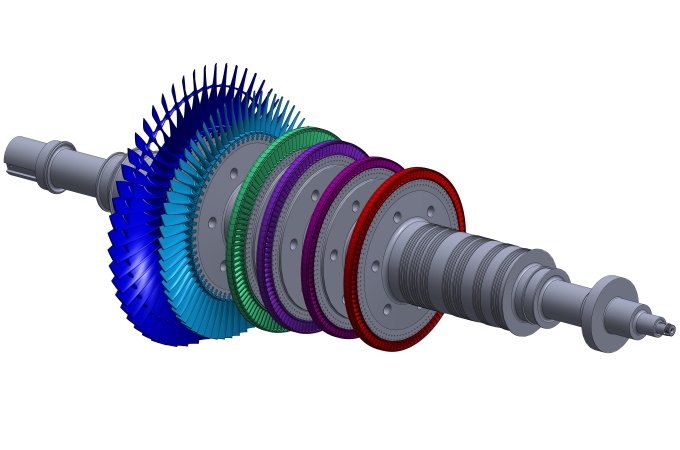

- Gas turbine

- From

- GE® Mark II to V control system

- To

- flexible and open control system based on PLCs (Siemens®, Schneider®, GE Fanuc® or Allen Bradley®)

- From

- Steam turbine

- From

- Electro-mechanical or electro-hydraulic

- Or ageing system : UG40

- To

- Woodward® 505

- Voith® Turcon™

- From

- Generator control and protection

- From

- Legacy ABB Unitrol™, ALSTHOM, …

- To

- Up to date ABB Unitrol™

- Basler® AVR

- From

TURBINE RELOCATION

If enhancing your production capabilities with a used turbine or changing the place of production, you will have to consider a turbine relocation.

SPIE Turbomachinery can help for :

- initial turbine condition assessment

- repair and overhaul

- adaptation study in its new process (steam circuit, electrical distribution, performance estimation, general arrangement, …)

- disassembly of turbine and auxiliaries

- transfer logistic

- reassembly on destination site

- commissioning

- new performance mapping

AUXILIARIES CONVERSIONS

Many auxiliaries can benefit from a conversion or a retrofit to enhance their reliability, efficiency, maintenability or simply to ensure durable spare part availability.

- air filter housing to new standards

- lube oil system renewal according to API 614

- hydraulic control oil system renewal

- electrical gas or steam control valves retrofit

- starting device technology modification (commonly diesel to electrical)

- atomizing air system enhancement

- liquid fuel forwarding and filtering system

- gas fuel filtering, heating and reducing system

TURBOMACHINE REDESIGN

It happens in an equipment lifetime that the operating conditions change or that the initial design didn’t take all operation constraints into account.

SPIE Turbomachinery’s engineering proposes lots of solutions to remedy through, even slight, design changes.

CASES

- steam turbine blade fir tree design change

- compressor impeller manufacturing process change

- steam turbine nozzle manufacturing process change

- adding proximiors in steam turbine